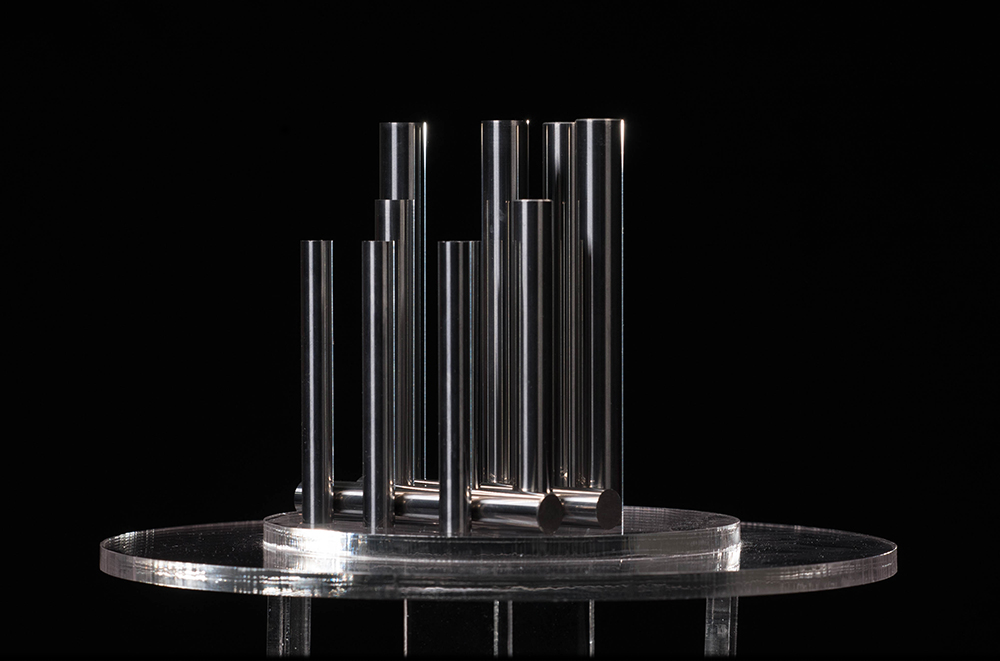

一直孔硬质合金棒材

单位:毫米

其他定制尺寸可以讨论。

| D | L | 乙 | 宽容 |

| 3.0 | 300/310/330 | 0.3 | ±0.1 |

| 4.0 | 300/310/330 | 0.6 | ±0.1 |

| 6.0 | 300/310/330 | 1 | ±0.15 |

| 8.0 | 300/310/330 | 1.3 | ±0.15 |

| 10.0 | 300/310/330 | 2 | ±0.2 |

| 12.0 | 300/310/330 | 2 | ±0.2 |

| 14.0 | 300/310/330 | 2 | ±0.2 |

| 16.0 | 300/310/330 | 2 | ±0.2 |

| 18.0 | 300/310/330 | 3 | ±0.25 |

| 20.0 | 300/310/330 | 3 | ±0.25 |

| 22.0 | 300/310/330 | 3 | ±0.25 |

| 24.0 | 300/310/330 | 4 | ±0.3 |

| 26.0 | 300/310/330 | 4 | ±0.3 |

| 28.0 | 300/310/330 | 4 | ±0.3 |

| 30.0 | 300/310/330 | 5 | ±0.35 |

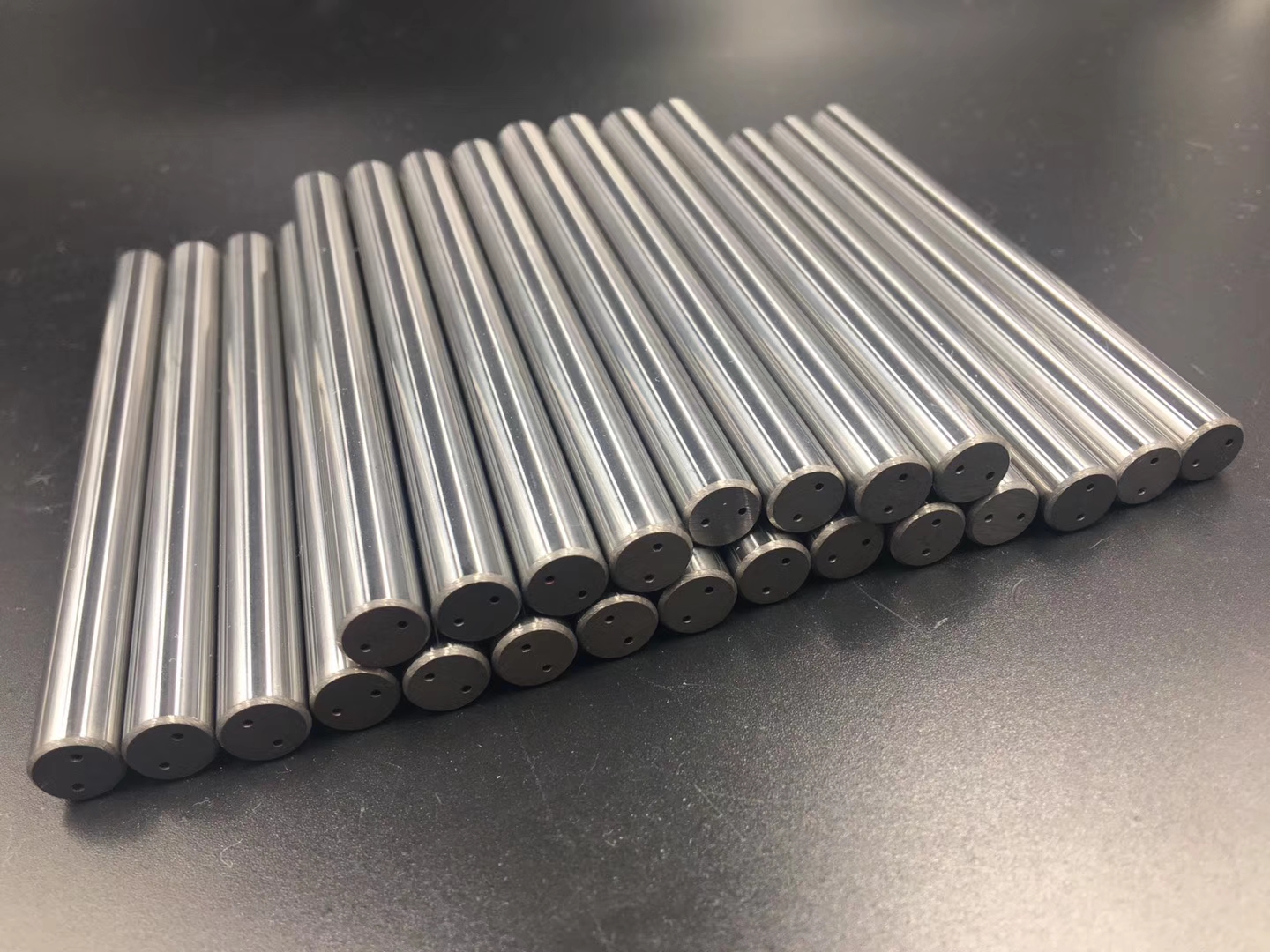

带两个直冷却孔的硬质合金棒

单位:毫米

| D | L | 乙 | 宽容 | TK | 宽容 |

| 3.0 | 300/310/330 | 0.4 | ±0.1 | 1.52 | ±0.08 |

| 4.0 | 300/310/330 | 0.8 | ±0.1 | 1.72 | ±0.08 |

| 5.0 | 300/310/330 | 0.8 | ±0.1 | 1.92 | ±0.08 |

| 6.0 | 300/310/330 | 1.0 | ±0.1 | 2.90 | ±0.1 |

| 7.0 | 300/310/330 | 1.0 | ±0.15 | 3.40 | ±0.1 |

| 8.0 | 300/310/330 | 1.0 | ±0.15 | 3.85 | ±0.15 |

| 9.0 | 300/310/330 | 1.4 | ±0.15 | 3.85 | ±0.15 |

| 10.0 | 300/310/330 | 1.4 | ±0.15 | 4.85 | ±0.15 |

| 11.0 | 300/310/330 | 1.4 | ±0.15 | 4.85 | ±0.15 |

| 12.0 | 300/310/330 | 1.8 | ±0.15 | 5.85 | ±0.15 |

| 13.0 | 300/310/330 | 1.8 | ±0.15 | 5.85 | ±0.15 |

| 14.0 | 300/310/330 | 1.8 | ±0.15 | 6.85 | ±0.15 |

| 15.0 | 300/310/330 | 2.0 | ±0.2 | 6.85 | ±0.15 |

| 16.0 | 300/310/330 | 2.0 | ±0.2 | 7.85 | ±0.15 |

| 17.0 | 300/310/330 | 2.0 | ±0.2 | 7.85 | ±0.15 |

| 18.0 | 300/310/330 | 2.0 | ±0.2 | 8.85 | ±0.15 |

| 19.0 | 300/310/330 | 2.0 | ±0.2 | 8.85 | ±0.15 |

| 20.0 | 300/310/330 | 2.5 | ±0.25 | 9.80 | ±0.2 |

| 21.0 | 300/310/330 | 2.5 | ±0.25 | 9.80 | ±0.2 |

| 22.0 | 300/310/330 | 2.5 | ±0.25 | 10.80 | ±0.2 |

| 23.0 | 300/310/330 | 2.5 | ±0.25 | 10.80 | ±0.2 |

| 24.0 | 300/310/330 | 3.0 | ±0.25 | 11.75 | ±0.25 |

| 25.0 | 300/310/330 | 3.0 | ±0.25 | 11.75 | ±0.25 |

| 26.0 | 300/310/330 | 3.0 | ±0.25 | 12.75 | ±0.25 |

带两个螺旋冷却孔的硬质合金棒

单位:毫米

| D | L | 乙 | 宽容 | TK | 宽容 | 沥青 ±0.5° |

| 3.0 | 300/310/330 | 0.4 | ±0.1 | 1.6 | ±0.1 | 16.32 |

| 4.0 | 300/310/330 | 0.6 | ±0.1 | 2.1 | ±0.1 | 21.77 |

| 5.0 | 300/310/330 | 0.7 | ±0.1 | 2.4 | ±0.2 | 27.21 |

| 6.0 | 300/310/330 | 0.7 | ±0.1 | 2.4 | ±0.2 | 32.65 |

| 7.0 | 300/310/330 | 1 | ±0.15 | 3.5 | ±0.2 | 38.09 |

| 8.0 | 300/310/330 | 1 | ±0.15 | 3.8 | ±0.2 | 43.53 |

| 9.0 | 300/310/330 | 1.4 | ±0.15 | 4.5 | ±0.3 | 48.97 |

| 10.0 | 300/310/330 | 1.4 | ±0.15 | 4.5 | ±0.3 | 54.41 |

| 11.0 | 300/310/330 | 1.4 | ±0.15 | 4.9 | ±0.4 | 59.86 |

| 12.0 | 300/310/330 | 1.4 | ±0.15 | 5.85 | ±0.4 | 65.3 |

| 13.0 | 300/310/330 | 1.75 | ±0.2 | 6.1 | ±0.4 | 70.74 |

| 14.0 | 300/310/330 | 1.75 | ±0.2 | 6.7 | ±0.4 | 76.18 |

| 15.0 | 300/310/330 | 1.75 | ±0.2 | 7.3 | ±0.4 | 81.62 |

| 16.0 | 300/310/330 | 1.75 | ±0.2 | 7.9 | ±0.4 | 87.06 |

| 17.0 | 300/310/330 | 1.75 | ±0.2 | 8.5 | ±0.4 | 92.5 |

| 18.0 | 300/310/330 | 2 | ±0.25 | 9.15 | ±0.4 | 97.95 |

| 19.0 | 300/310/330 | 2 | ±0.25 | 9.7 | ±0.4 | 103.39 |

| 20.0 | 300/310/330 | 2 | ±0.25 | 9.9 | ±0.5 | 108.83 |

| 22.0 | 300/310/330 | 2 | ±0.25 | 11.1 | ±0.5 | 125.15 |

| 25.0 | 300/310/330 | 2 | ±0.25 | 12.8 | ±0.5 | 136.05 |