2/4 Flutes Solid Flattened Carbide End Mill

HRC50 For General Machining

| Product Name | 2/4 flutes HRC50° tungsten carbide end milling cutter |

| HRC | 50° |

| Coating | AlTiN, High aluminum content, Black |

| Flute | 2/4 |

| Material | Tungsten Carbide Rod |

| Applicable materials | HRC≤50 Alloy steel, nonferrous metal, gray cast iron, common dia steel, heat resistant alloy steel. |

Excellent and stable performance

The raw material is foundation of quality, we use our own grade CF10 tungsten carbide rod, which has high wear resistance and strength.

The performance will be consistent and long service life.

Tungsten Carbide Rod Material

| Grade | Co | WC grain size | Hardness | T.R.S |

|---|---|---|---|---|

| CF10 | 10% | 0.8μm | HRA 91.7 | 3600N/mm² |

TiAlN Coating

The blade is covered with a TiALN coating and increases the wear resistance of the milling cutter. It can be used for rough or finish machining under HRC50 material.

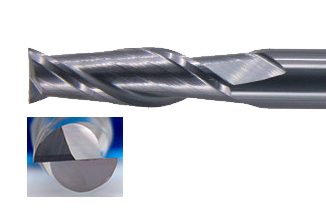

Blade design for stable

Two blades with helical chip removal

It is not easy to collapse, enhance end mill chip removal ability, so that the cutting ability of the tool is more stable.

Chamfer Design

Enhance the shock resistance of the milling cutter.

| Standard Size | ||||

|---|---|---|---|---|

| d | l | D | L | F |

| 1.0 | 3 | 4 | 50 | 2/4 |

| 1.5 | 4 | 4 | 50 | 2/4 |

| 2.0 | 6 | 4 | 50 | 2/4 |

| 2.5 | 7 | 4 | 50 | 2/4 |

| 3.0 | 8 | 3/4 | 50 | 2/4 |

| 3.5 | 10 | 4 | 50 | 2/4 |

| 4.0 | 11 | 4 | 50 | 2/4 |

| 5.0 | 13 | 5 | 50 | 2/4 |

| 5.0 | 13 | 6 | 50 | 2/4 |

| 6.0 | 16 | 6 | 50 | 2/4 |

| 7.0 | 20 | 8 | 60 | 2/4 |

| 8.0 | 20 | 8 | 60 | 2/4 |

| 9.0 | 25 | 10 | 75 | 2/4 |

| 10.0 | 25 | 10 | 75 | 2/4 |

| 11.0 | 30 | 12 | 75 | 2/4 |

| 12.0 | 30 | 12 | 75 | 2/4 |

| 13.0 | 35 | 14 | 80 | 2/4 |

| 14.0 | 35 | 14 | 80 | 2/4 |

| 15.0 | 40 | 16 | 100 | 2/4 |

| 16.0 | 40 | 16 | 100 | 2/4 |

| 18.0 | 45 | 18 | 100 | 2/4 |

| 20.0 | 45 | 20 | 100 | 2/4 |

| Lengthening | ||||

|---|---|---|---|---|

| d | l | D | L | F |

| 1.0 | 5 | 4 | 75 | 2/4 |

| 2.0 | 9 | 4 | 75 | 2/4 |

| 2.5 | 10 | 4 | 75 | 2/4 |

| 3.0 | 15 | 3/4 | 75 | 2/4 |

| 3.0 | 15 | 3/4 | 100 | 2/4 |

| 4.0 | 20 | 4 | 75 | 2/4 |

| 4.0 | 20 | 4 | 100 | 2/4 |

| 5.0 | 25 | 5 | 75 | 2/4 |

| 5.0 | 25 | 5 | 100 | 2/4 |

| 5.0 | 25 | 6 | 75 | 2/4 |

| 5.0 | 25 | 6 | 100 | 2/4 |

| 6.0 | 25 | 6 | 75 | 2/4 |

| 6.0 | 25 | 6 | 100 | 2/4 |

| 8.0 | 30 | 8 | 75 | 2/4 |

| 8.0 | 30 | 8 | 100 | 2/4 |

| 8.0 | 30 | 8 | 150 | 2/4 |

| 10.0 | 40 | 10 | 100 | 2/4 |

| 10.0 | 50 | 10 | 150 | 2/4 |

| 12.0 | 45 | 12 | 100 | 2/4 |

| 12.0 | 55 | 12 | 150 | 2/4 |

| 14.0 | 35 | 14 | 100 | 2/4 |

| 14.0 | 60 | 14 | 150 | 2/4 |

| 16.0 | 70 | 16 | 150 | 2/4 |

| 18.0 | 70 | 18 | 150 | 2/4 |

| 20.0 | 80 | 20 | 150 | 2/4 |

| Workpiece material | HRC -30 | HRC 30-35 | HRC35-40 | HRC40-45 | HRC 45-60 | |||||

| d | Rotating | Feed | Rotating | Feed | Rotating | Feed | Rotating | Feed | Rotating | Feed |

| mm | r/min | mm/min | r/min | mm/min | r/min | mm/min | r/min | mm/min | r/min | mm/min |

| 1 | 16000 | 120 | 9500 | 75 | 7600 | 70 | 5700 | 66 | 3200 | 24 |

| 2 | 9500 | 160 | 5700 | 105 | 4500 | 95 | 3300 | 82 | 1900 | 35 |

| 3 | 7400 | 220 | 4500 | 140 | 3600 | 125 | 2600 | 110 | 1500 | 46 |

| 4 | 6400 | 300 | 3800 | 180 | 3000 | 160 | 2200 | 150 | 1270 | 60 |

| 5 | 5700 | 370 | 3400 | 220 | 2700 | 200 | 2000 | 180 | 1150 | 75 |

| 6 | 5300 | 480 | 3200 | 290 | 2500 | 260 | 1900 | 220 | 800 | 96 |

| 8 | 4000 | 480 | 2400 | 290 | 1900 | 260 | 1400 | 220 | 800 | 96 |

| 10 | 3200 | 480 | 1900 | 290 | 1500 | 250 | 1100 | 210 | 640 | 93 |

| 12 | 2600 | 460 | 1600 | 280 | 1300 | 250 | 950 | 210 | 530 | 93 |

| 16 | 2000 | 360 | 1200 | 220 | 950 | 200 | 710 | 170 | 400 | 72 |

| 20 | 1600 | 290 | 950 | 170 | 760 | 150 | 570 | 135 | 320 | 57 |