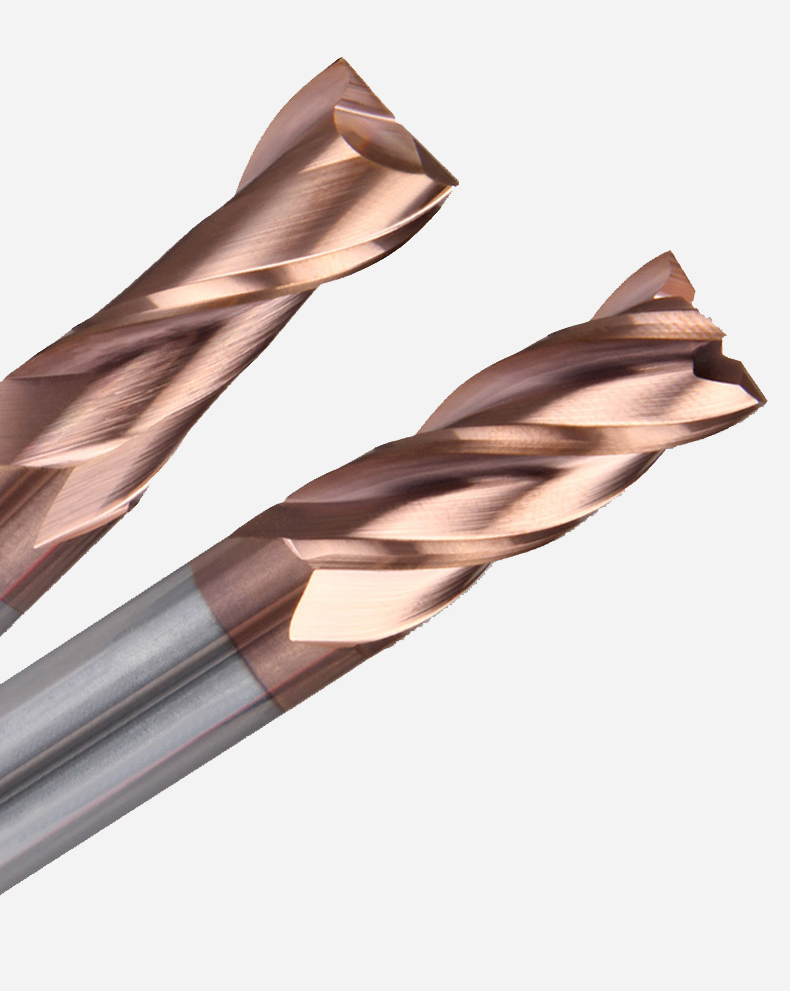

HRC55 Tungsten Carbide End Milling Cutter

| Product Name | 2/4 flutes Flattened solid carbide end mill cutter |

| Material | Grade CF12 tungsten carbide rod |

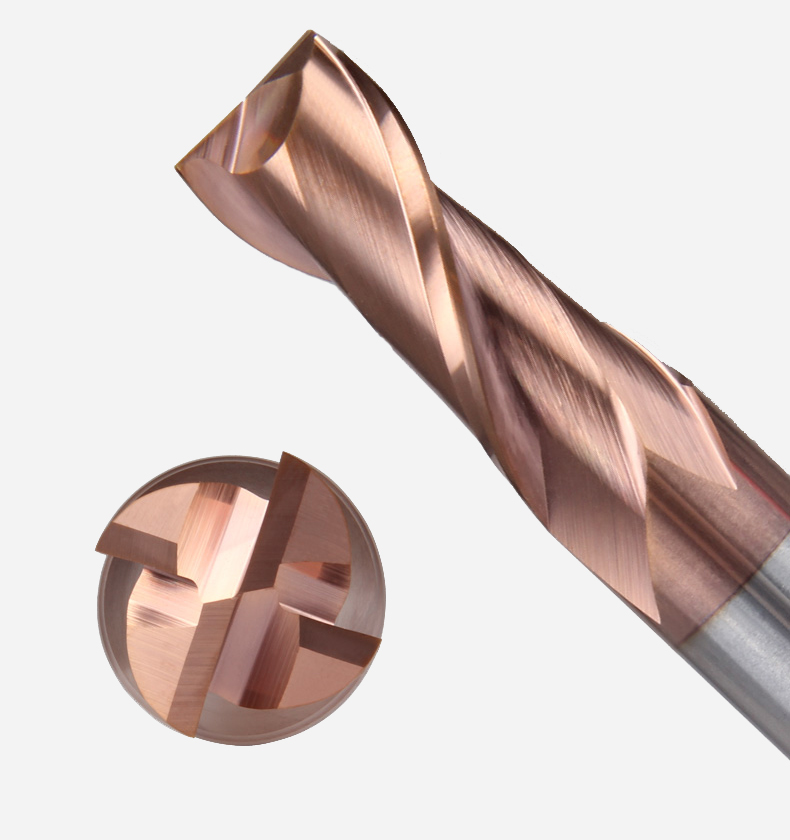

| Flutes | 2/3/4/6 |

| Hardness | HRC55 |

| Helix Angle | 35° |

| Coating | TiSiN、silicon titanium, Bronze |

| Applicable materials | Die prehardened steel, Quendched Steel, alloy steel, tool steel etc |

| Feature | Excellent chip evacuation, design for durable, high efficiency |

High Efficiency, Long Service Life & Seismic Stability

Using grade CF12 HIP tungsten carbide rod with 12%Co. We controled the production of supply chain from tungsten carbide powder- tungsten carbide rod- carbide end milling cutter, the consistence of performance will be better

Tungsten Carbide Rod Material

| Grade | Co | WC grain size | Hardness | T.R.S |

|---|---|---|---|---|

| CF12 | 12% | 0.6μm | HRA 92.3 | 3800N/mm² |

Sharp Cutting Edge

Both of the radial direction and the axial direction are sharp and large cutting angles.

Smooth Chip Removal Design

Excellent aseismic design makes the surface finish better

| Standard Size | ||||

|---|---|---|---|---|

| d | l | D | L | F |

| 1.0 | 3 | 4 | 50 | 2/4 |

| 1.5 | 4 | 4 | 50 | 2/4 |

| 2.0 | 6 | 4 | 50 | 2/4 |

| 2.5 | 7 | 4 | 50 | 2/4 |

| 3.0 | 8 | 3/4 | 50 | 2/4 |

| 3.5 | 10 | 4 | 50 | 2/4 |

| 4.0 | 11 | 4 | 50 | 2/4 |

| 5.0 | 13 | 5 | 50 | 2/4 |

| 5.0 | 13 | 6 | 50 | 2/4 |

| 6.0 | 16 | 6 | 50 | 2/4 |

| 7.0 | 20 | 8 | 60 | 2/4 |

| 8.0 | 20 | 8 | 60 | 2/4 |

| 9.0 | 25 | 10 | 75 | 2/4 |

| 10.0 | 25 | 10 | 75 | 2/4 |

| 11.0 | 30 | 12 | 75 | 2/4 |

| 12.0 | 30 | 12 | 75 | 2/4 |

| 13.0 | 35 | 14 | 80 | 2/4 |

| 14.0 | 35 | 14 | 80 | 2/4 |

| 15.0 | 40 | 16 | 100 | 2/4 |

| 16.0 | 40 | 16 | 100 | 2/4 |

| 18.0 | 45 | 18 | 100 | 2/4 |

| 20.0 | 45 | 20 | 100 | 2/4 |

| Lengthening | ||||

|---|---|---|---|---|

| d | l | D | L | F |

| 1.0 | 5 | 4 | 75 | 2/4 |

| 2.0 | 9 | 4 | 75 | 2/4 |

| 2.5 | 10 | 4 | 75 | 2/4 |

| 3.0 | 15 | 3/4 | 75 | 2/4 |

| 3.0 | 15 | 3/4 | 100 | 2/4 |

| 4.0 | 20 | 4 | 75 | 2/4 |

| 4.0 | 20 | 4 | 100 | 2/4 |

| 5.0 | 25 | 5 | 75 | 2/4 |

| 5.0 | 25 | 5 | 100 | 2/4 |

| 5.0 | 25 | 6 | 75 | 2/4 |

| 5.0 | 25 | 6 | 100 | 2/4 |

| 6.0 | 25 | 6 | 75 | 2/4 |

| 6.0 | 25 | 6 | 100 | 2/4 |

| 8.0 | 30 | 8 | 75 | 2/4 |

| 8.0 | 30 | 8 | 100 | 2/4 |

| 8.0 | 30 | 8 | 150 | 2/4 |

| 10.0 | 40 | 10 | 100 | 2/4 |

| 10.0 | 50 | 10 | 150 | 2/4 |

| 12.0 | 45 | 12 | 100 | 2/4 |

| 12.0 | 55 | 12 | 150 | 2/4 |

| 14.0 | 35 | 14 | 100 | 2/4 |

| 14.0 | 60 | 14 | 150 | 2/4 |

| 16.0 | 70 | 16 | 150 | 2/4 |

| 18.0 | 70 | 18 | 150 | 2/4 |

| 20.0 | 80 | 20 | 150 | 2/4 |

| Workpiece material | HRC -30 | HRC 30-35 | HRC35-40 | HRC40-45 | HRC 45-60 | |||||

| d | Rotating | Feed | Rotating | Feed | Rotating | Feed | Rotating | Feed | Rotating | Feed |

| mm | r/min | mm/min | r/min | mm/min | r/min | mm/min | r/min | mm/min | r/min | mm/min |

| 1 | 16000 | 120 | 9500 | 75 | 7600 | 70 | 5700 | 66 | 3200 | 24 |

| 2 | 9500 | 160 | 5700 | 105 | 4500 | 95 | 3300 | 82 | 1900 | 35 |

| 3 | 7400 | 220 | 4500 | 140 | 3600 | 125 | 2600 | 110 | 1500 | 46 |

| 4 | 6400 | 300 | 3800 | 180 | 3000 | 160 | 2200 | 150 | 1270 | 60 |

| 5 | 5700 | 370 | 3400 | 220 | 2700 | 200 | 2000 | 180 | 1150 | 75 |

| 6 | 5300 | 480 | 3200 | 290 | 2500 | 260 | 1900 | 220 | 800 | 96 |

| 8 | 4000 | 480 | 2400 | 290 | 1900 | 260 | 1400 | 220 | 800 | 96 |

| 10 | 3200 | 480 | 1900 | 290 | 1500 | 250 | 1100 | 210 | 640 | 93 |

| 12 | 2600 | 460 | 1600 | 280 | 1300 | 250 | 950 | 210 | 530 | 93 |

| 16 | 2000 | 360 | 1200 | 220 | 950 | 200 | 710 | 170 | 400 | 72 |

| 20 | 1600 | 290 | 950 | 170 | 760 | 150 | 570 | 135 | 320 | 57 |