Tungsten Carbide Rods

The Tungsten Carbide Rods(also named as Cemented Carbide Rods), are used in making high quality carbide cutting tools for the machining of heat-resistant alloys and Ti alloy, such as end mill, drill, reamer.

1. Grade: ISO K05-K40

2. Dia: 2mm-50mm; Length: Standard or customized

Unground Tungsten Carbide Rods Blanks

Grade Performances of Tungten Carbide Rod

| Type | Grade | ISO | Grain Size of Wc | Content of Co | Density | Hardness | TRS(/MPa) |

| For Cutting | CF12 | K30-K40 | 0.6μm | 12% | 14.1g/cm³ | HRA92.3 | 3800 |

| CF10 | K20-K30 | 0.8μm | 10% | 14.4g/cm³ | HRA91.8 | 3600 | |

| CF6UF | K10 | 0.4μm | 6% | 14.85g/cm³ | HRA94 | 3800 | |

| CF8UF | K20 | 0.4μm | 8% | 14.6g/cm³ | HRA93.2 | 3800 | |

| For Stamping | CFK3 | / | 0.8-1.0μm | 13% | 14.06g/cm³ | HRA90.5-91 | 3600 |

| F7 | / | 1.0μm | 15% | 13.85g/cm³ | HRA89-89.5 | 3800 |

| Grade | Recommend Application | ||||||

| CF10 | Stable performance fine grain size material, general purpose for steel, cast iron, aluminum, copper, heat-resistant alloy etc. Suitbale for making end mills, drills, reamers etc. | ||||||

| CF12 | Having high wear-resistance and excellent shock-resistance, suitbale for milling and drilling stainless steel, hardened steel, aluminum alloy, nickel base alloy etc. | ||||||

| CF6UF | Super-fine grain size material, Suitable for machining aluminum-magnesium alloys, glass fiber, carbon fiber, wood, harden plastic etc. For making PCB micro tools and drills of other material. | ||||||

| CF8UF | Suitable for machining glass fiber, wood, titanium alloy, stainless steel, copper-aluminum alloy etc. For making drill, end mill, graver and micro-drill with diameter less than 0.8mm used for machining of PCB. | ||||||

| Diameter | Tolerance | Length | Tolerance | Diameter | Tolerance | Length | Tolerance |

| 2.0 | +0.15/+0.30 | 330 | -0/+5.0 | 16.0 | +0.30/+0.60 | 330 | -0/+5.0 |

| 3.0 | +0.15/+0.30 | 330 | -0/+5.0 | 17.0 | +0.30/+0.60 | 330 | -0/+5.0 |

| 4.0 | +0.25/+0.40 | 330 | -0/+5.0 | 18.0 | +0.30/+0.60 | 330 | -0/+5.0 |

| 5.0 | +0.25/+0.40 | 330 | -0/+5.0 | 19.0 | +0.30/+0.60 | 330 | -0/+5.0 |

| 6.0 | +0.25/+0.40 | 330 | -0/+5.0 | 20.0 | +0.30/+0.60 | 330 | -0/+5.0 |

| 7.0 | +0.25/+0.40 | 330 | -0/+5.0 | 21.0 | +0.30/+0.80 | 330 | -0/+5.0 |

| 8.0 | +0.25/+0.40 | 330 | -0/+5.0 | 22.0 | +0.30/+0.80 | 330 | -0/+5.0 |

| 9.0 | +0.25/+0.40 | 330 | -0/+5.0 | 23.0 | +0.30/+0.80 | 330 | -0/+5.0 |

| 10.0 | +0.25/+0.40 | 330 | -0/+5.0 | 24.0 | +0.30/+0.80 | 330 | -0/+5.0 |

| 11.0 | +0.25/+0.50 | 330 | -0/+5.0 | 25.0 | +0.30/+0.80 | 330 | -0/+5.0 |

| 12.0 | +0.25/+0.50 | 330 | -0/+5.0 | 26.0 | +0.30/+0.80 | 330 | -0/+5.0 |

| 13.0 | +0.25/+0.50 | 330 | -0/+5.0 | 27.0 | +0.30/+0.80 | 330 | -0/+5.0 |

| 14.0 | +0.25/+0.50 | 330 | -0/+5.0 | 28.0 | +0.30/+0.80 | 330 | -0/+5.0 |

| 15.0 | +0.30/+0.60 | 330 | -0/+5.0 | 29.0 | +0.30/+0.80 | 330 | -0/+5.0 |

| Tolerance Grade For Ground Rods | |||||||

| Diameter (mm) | h5 | h6 | h7 | ||||

| 0-3.0 | 0.004 | 0.006 | 0.01 | ||||

| 3.001-6.0 | 0.005 | 0.008 | 0.012 | ||||

| 6.001-10.0 | 0.006 | 0.009 | 0.015 | ||||

| 10.001-17 | 0.008 | 0.011 | 0.018 | ||||

| 18.001-30.0 | 0.009 | 0.013 | 0.021 | ||||

| 30.001-50.0 | 0.011 | 0.016 | 0.025 | ||||

| Diameter ≤50mm, cut length can be supplied at customers’ request. | |||||||

How does Tungsten Carbide Rods Manufacture

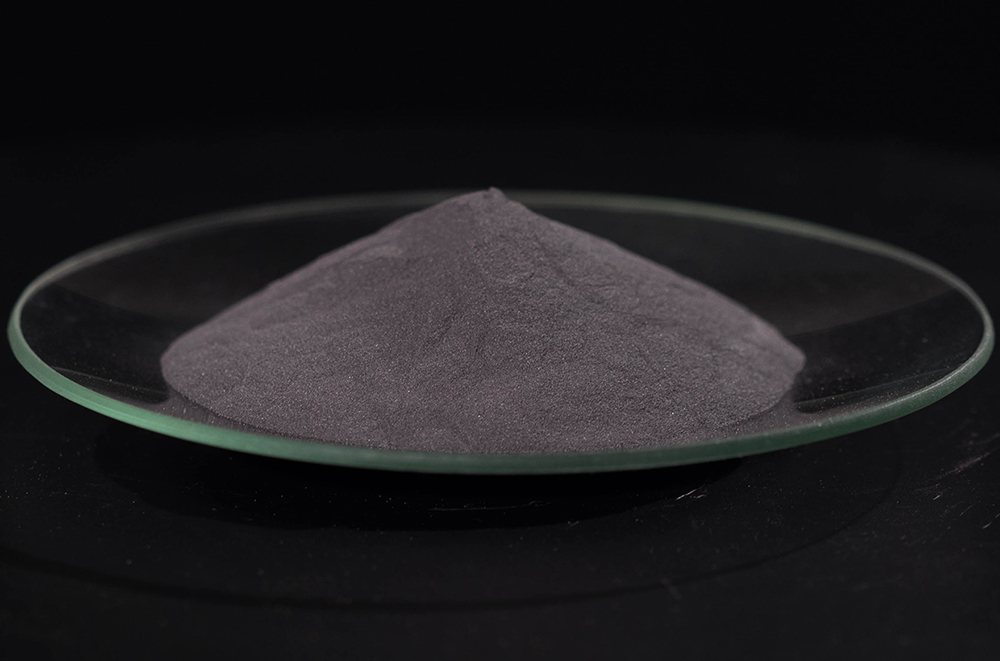

Wet Milling

We use Fine and Ultra Fine grain size of tungsten carbide powder. To control uniform grain size, wet milling is the first step.

Extrusion

Before extrusion, it shoud be dried and granulated. Extrusion is the main way to press long carbide rods like 300, 310,330mm. We manage diffrent diameter carbide rods with different extrusion machine to improve production efficiency. We can manage diameter from 2-30mm.

HIP Sintering

Sintered under 6Mpa pressuer and 1400℃+ .

Every batch after sintered, we will analysis firstly. Coercive force, Hardness, TRS, Density, Metallographic. To ensure the carbide rods we send to customer is qualified.

Cutting to short

The sintered tungsten carbide rods is 300-330mm standard length, The auto cutting machine was needed to cut it to standard or nonstandard short carbide rods as required like 45mm, 50mm, 150mm long etc.

The next step is Precision Grinding, we plan to add grind machine to service customer.